Loading... Please wait...

Loading... Please wait...Categories

- 3D Filament

- Laser Parts

- 3D Printers

- 3D Printer Parts

- Microcontrollers and FPGA

- Shields and daughter boards

- Official Arduino

- Batteries

- Cases and Enclosures

- Cables and Connectors

- CNC

- Components

- Digi XBee

- Displays

- Electronic Brick

- Kits

- Laser Cutters

- LEDs

- Micro:bit

- Motors

- Neodymium Magnets

- Power Supply and Adapter

- Python

- Raspberry Pi

- RFID

- Robotics

- Sensors

- Soldering Equipment

- Tools

- Wearables

- Wireless

- Home

- 3D Printers

- Original Prusa MK4S (Assembled Printer)

Product Description

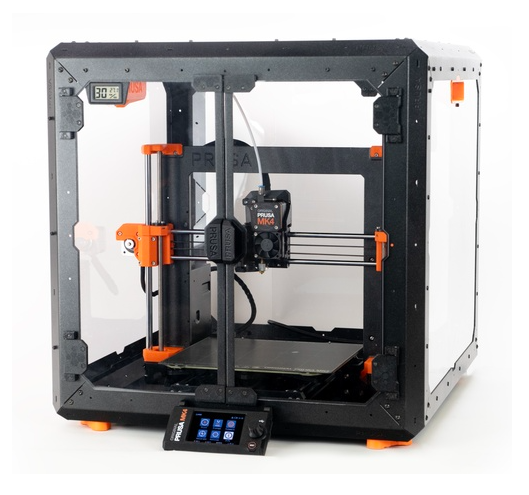

The Original Prusa MK4S delivers reliable results for all your projects. Building on the MK4 model loved by hobbyists and big companies alike, it offers even higher accuracy and print speed. Thanks to its new 360° cooling, high-flow nozzle, and numerous firmware optimizations, you’ll get your 3D models fast and with top-notch quality.

The Original Prusa MK4S is built around Prusa's new 32-bit connected architecture and the next-generation extruder (Nextruder). It lays down a perfect first layer every time without Live Adjust Z and it has support for high-speed printing with Input Shaper and Pressure Advance. Prusa also improved the safety features even further. Plus, there are a ton of useful things, such as quick-swap nozzles, built-in support for remote printing and webcams, and many more. And it’s still beautifully quiet.

- The successor to the award-winning 3D printing workhorse Original Prusa MK4

- Effortlessly fast and silent 3D printing.

- Fully automatic first layer calibration thanks to the Load Cell sensor

- Print right out of the box - no print sheets profiles, no tinkering, no Live Adjust Z!

- Nextruder – Prusa's new extruder with a custom breakout board and smart features

- Safety features like filament sensor and power panic that won't let you down

- Easy maintenance, quick-swap nozzles, and removable print sheets

- Support for a wide range of materials, incl. PLA, PETG, Flex, Nylon, ASA, PVA, PC, PP, composites and more

- Color LCD screen with simple-to-navigate UI and quick access to all important functions

- Ethernet and Wi-fi connection

- Open-source

Main Features

|

Perfect for Pros and BeginnersThe MK4S answers your needs whether you’re just starting or have years of experience. We’ve designed the UI to be easy to use even for complete beginners, yet its reliable performance also makes it a perfect fit for professional workshops. Getting started is super easy: simply take the MK4S out of the box, plug it in, perform a quick calibration, and start printing in 15 minutes! |

|

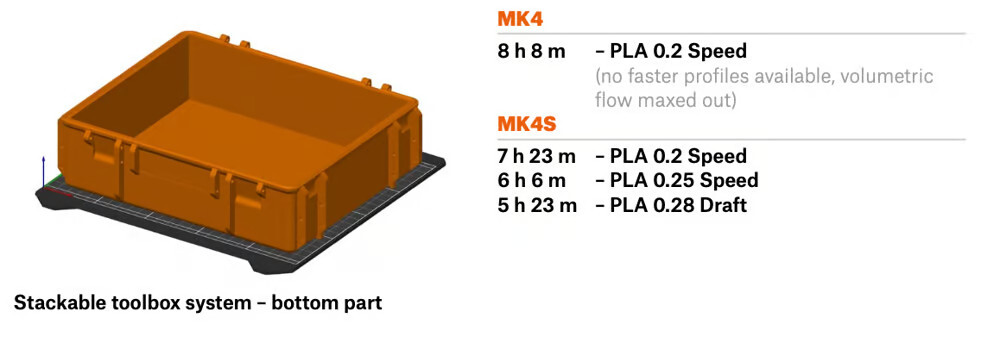

World-Class Print SpeedAs Tom’s Hardware puts it: The Prusa MK4S is pretty darn fast. It substantially cuts print times thanks to the new cooling fan with a powerful turbine and 360° air delivery, as well as the high-flow nozzle that allows for maximized filament flow. Combined with optimized firmware and print profiles, the results are both quick and flawless. |

|

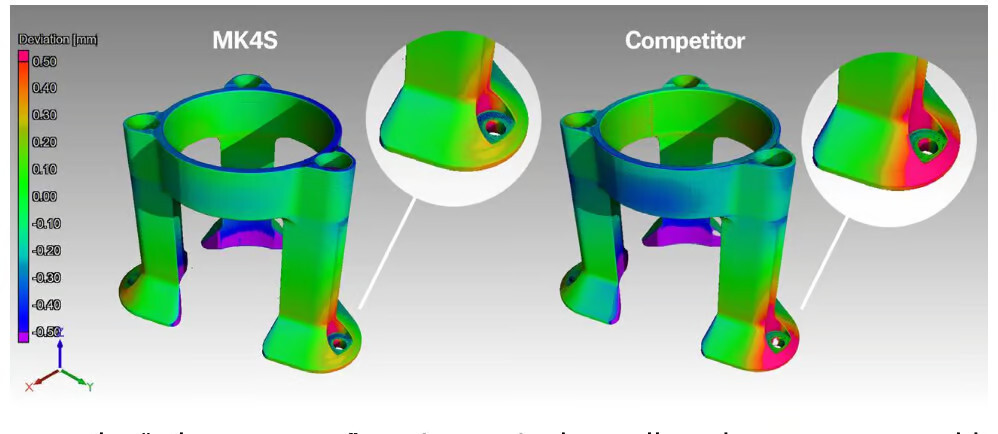

Perfect Dimensional AccuracyYour creations should turn out precisely as designed, especially when they require a perfect fit. The MK4S ensures that by delivering exceptionally accurate prints. See the accuracy comparison measured using a CT scan: |

|

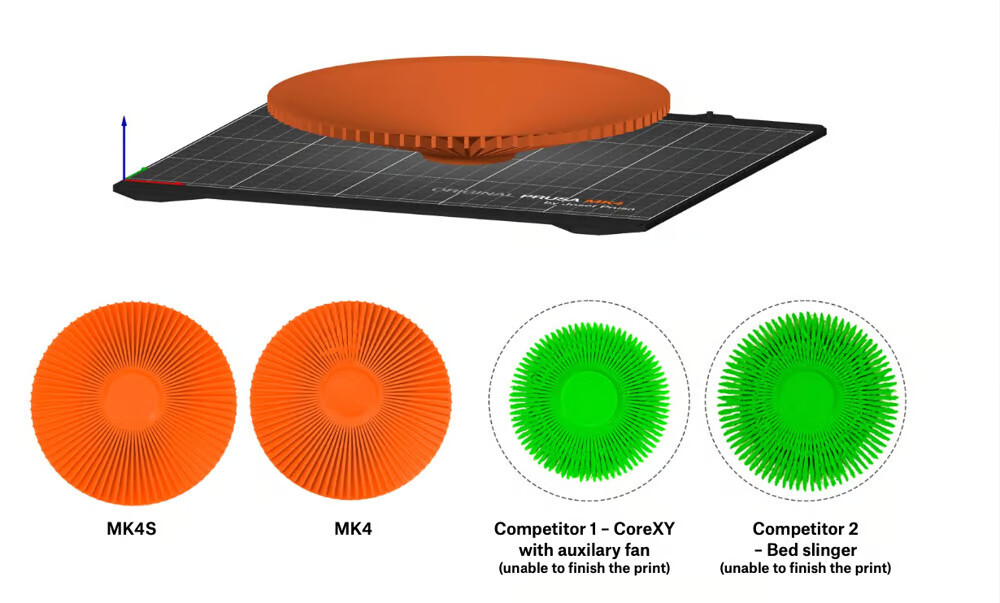

360° Cooling – Print without SupportsReduce the need for supports and print quicker with less material! Thanks to the 360° cooling, the MK4S allows you to print overhangs of up to 75° without supports, significantly cutting down on print costs and time. This also simplifies printing flexible materials like TPU, where removing supports is often a challenge. |

|

Perfect Surface FinishYour models turn out smooth and a joy to look at, as the MK4S’ print profiles prioritize perfect surface finishes. You can adjust print layer height to match your desired level of detail and print everything from super intricate models (with the 0.25mm nozzle) to larger objects, where details matter less. |

|

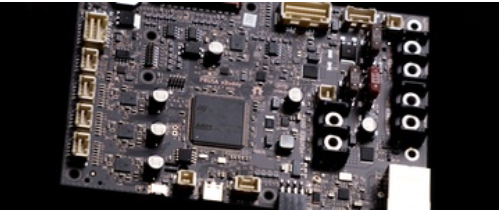

32-bit xBuddy MainboardOur new xBuddy board is a 32-bit STM32-powered mainboard with many great features. It has several unique hardware-based safety protection systems, communicates with four thermistors, has all important ports (Ethernet, Wi-Fi, works with USB-A flash drives) and more. The entire board was designed, manufactured, and tested in-house. |

|

Color LCD screen and simple UIMK4S’s display supports G-code thumbnails, QR codes and other elements that make using the printer so much easier. We also redesigned many of the existing menus and added a customizable footer panel. Directly under the LCD, there is an RGB status bar to signalize the current status of the printer. Next to the LCD, there’s a USB-A port for standard USB flash drives. |

|

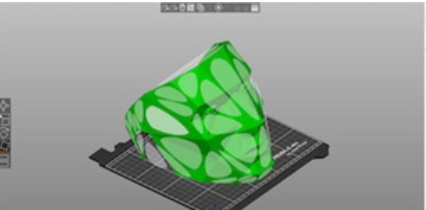

Slice with PrusaSlicerOur internally developed multiplatform slicer comes with in-house made and fully tested profiles for all of our 3D printers and a wide range of filaments. With built-in tools, such as organic supports, cutting, automated object distribution, ironing and many others, you will turn your 3D models into print files in no time! |

|

Prusa Connect and Connectivity OptionsMK4 is, along our other 3D printers, fully supported by Prusa Connect, which allows you to control the printer via internet. You can drag-and-drop G-Codes into the browser window to upload print files first into the cloud (each user gets 2 GB for free) and then transfer it into the printer’s USB storage and start the print remotely. All communication is encrypted. |

Technical Parameters

| Build Volume | 250 x 210 x 220 mm | 9.84 x 8.3 x 8.6 in |

| Filament diameter> | 1.75 mm |

| Layer height | 0.05-0.30 mm |

| Mainboard | Custom 32-bit xBuddy electronics with STM32 |

| Stepper Drivers | Trinamic 2130 |

| Stepper motors | Precise 0.9° X,Y stepper motors (prevents VFA) |

| Extruder | Nextruder, Direct Drive, E3D V6 compatible (with adapter) |

| Extruder electronics | Custom breakout board for connecting fans, thermistors and other parts. |

| Filament path | Aluminum heatsink, all-metal hotend, no PTFE tube |

| Drive system |

Nextruder Planetary Gear System, 10:1 gearbox ratio |

| Cooling fan |

High-performance turbine, 360° cooling system |

| Nozzle |

High-flow Prusa Nozzle brass CHT - 0.4 mm |

| Nozzle diameter |

0.4mm (default) / other nozzle diameters supported |

| Max nozzle temperature | 290 °C / 572 °F |

| Max heatbed temperature | 120 °C / 248 °F |

| LCD screen | 3.5″ graphic 65k color screen |

| Connectivity | NFC receiver, optional ESP Wi-Fi module (delivered with the printer) |

| Print medium | USB drive / LAN / internet via Prusa Connect |

| Advanced sensors | Filament sensor, Loadcell sensor, Power panic, 4 high-precision thermistors (genuine Semitec) + fan motors RPM monitoring |

| Print surface | Magnetic heatbed with removable PEI spring steel sheets |

| Bed calibration | Automatic, Mesh Bed Leveling (only on print area) |

| Supported materials | PLA, PETG, ABS, ASA, Flex, HIPS, PA, PVA, PC, PP, CPE, PVB(with enclosure), NGEN, composites and more |

| Printer dimensions (without spool) | 7 kg, 500×550×400 mm; 19.6×21.6×15.7 in (X×Y×Z) |

| PSU | 240W, custom made by Delta with Power Panic HW |

| Power consumption | PLA settings: 80W / ABS settings: 120W |

* Consumable parts, such as print sheets (smooth, textured, etc.), are not covered by the warranty since their coatings are expected to deteriorate over time, unless the failure is due to a defect in materials or workmanship. Cosmetic damage, which includes, but is not limited to, scratches, dents, cracks, or other aesthetic damage, is also not covered. Only sheets defective upon delivery are covered by the warranty.

Add-ons

They are sold separately, as an additional item

Ready for multi-color printing with MMU3MK4 can be enhanced by an optional add-on that allows your single-extruder printer to print with up to 5 colors (materials) at the same time. The MMU3 contains five filament insertion points. Load the five colors of your choice, slice the object with MMU3 profile in PrusaSlicer and start the print. The system automatically selects filament using the selector, loads it into the Nextruder and the MK4 starts printing. When it’s time to change the color or material, it also happens automatically. The MMU3 is the latest edition of Multi Material printing device by Prusa Research. The firmware has been rewritten completely, we have redesigned the plastic parts, added more robust metal parts, improved the electronics and updated the filament buffer. All of these changes have improved the reliability and user comfort to levels where MMU has never been before. Ask to consultas@crcibernetica.com to get a quote |

|

|

Enclosure availableMK4S is fully compatible with the Original Prusa Enclosure. If you want to print more advanced technical materials on your MK4S, you’ll find the Enclosure really handy. It stabilizes the printer environment, eliminates drafts and odors, and makes the printer even more silent. Ask to consultas@crcibernetica.com to get a quote |

Package includes:

- Original Prusa MK4S Assembled 3D printer

- Double-sided Smooth PEI Print Sheet

- 1kg of Prusament PLA Galaxy Black

- 3D Printing Handbook

- USB drive with sample prints (G-codes)

- Toolset: Uni-wrench, 13-16 wrench, Philips screwdriver, Nose pliers, Allen and torx keys

- Alcohol-saturated wipes, acupuncture needle

- Spoolholder

- Spare parts package

- Prusa lubricant for bearings

- Manufacturing protocol

Documents:

- Prusa MK4S - EU Declaration of Conformity

- Prusa MK4S - UK Declaration of Conformity

- Certificate - UL2904